Complete Warehouse Automation & Staffing Solutions

Robotics • Labor • Software • Integration

Robots as a Service

Top-tier performance, fast, precise, and reliable, while keeping total cost of ownership low. No capex. Minimal maintenance. Maximum ROI.

Technical Specifications:

Atlas AC2000Load Capacity

4409 lbs

Maximum Speed

7.4 mph

Lift Height

11.8 ft

Technical Specifications:

Maia 2000Load Capacity

4409 lbs

Maximum Speed

5.6 mph

Lift Height

7 in

Click for more information

ATLAS

maia

Designed to augment

Warehouse Automation Made Simple

Designed to adapt seamlessly into any warehouse workflow, this modular, human aligned robotics system can be tailored to fit into any circumstance.

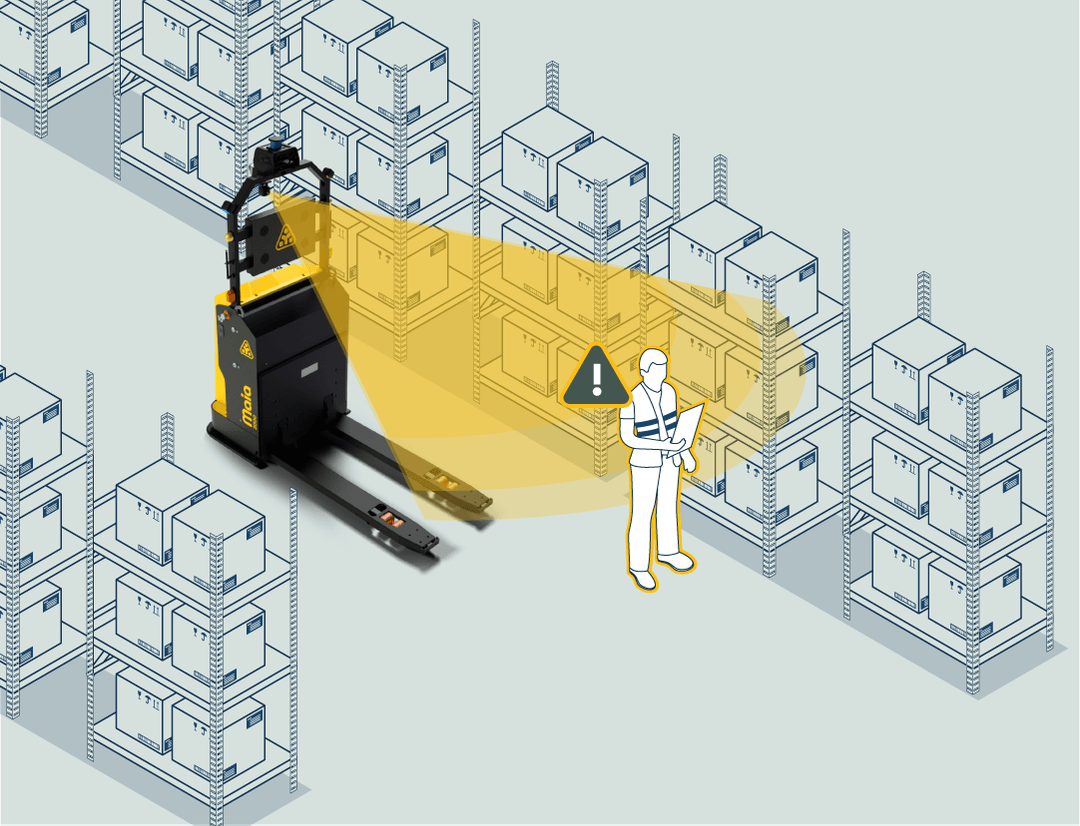

Safety

Every robot is engineered with layered safety mechanisms including 360° obstacle detection, real-time speed regulation, emergency stop systems, and human-aware navigation. All robots are equipped with a dedicated Programmable Logic Controller (PLC) that immediately halts movement if any obstacle is detected, ensuring instant response in critical moments. From hardware redundancies to intelligent decision logic, our design ensures safe operation in mixed-traffic environments, so people and robots can work side by side with total confidence.

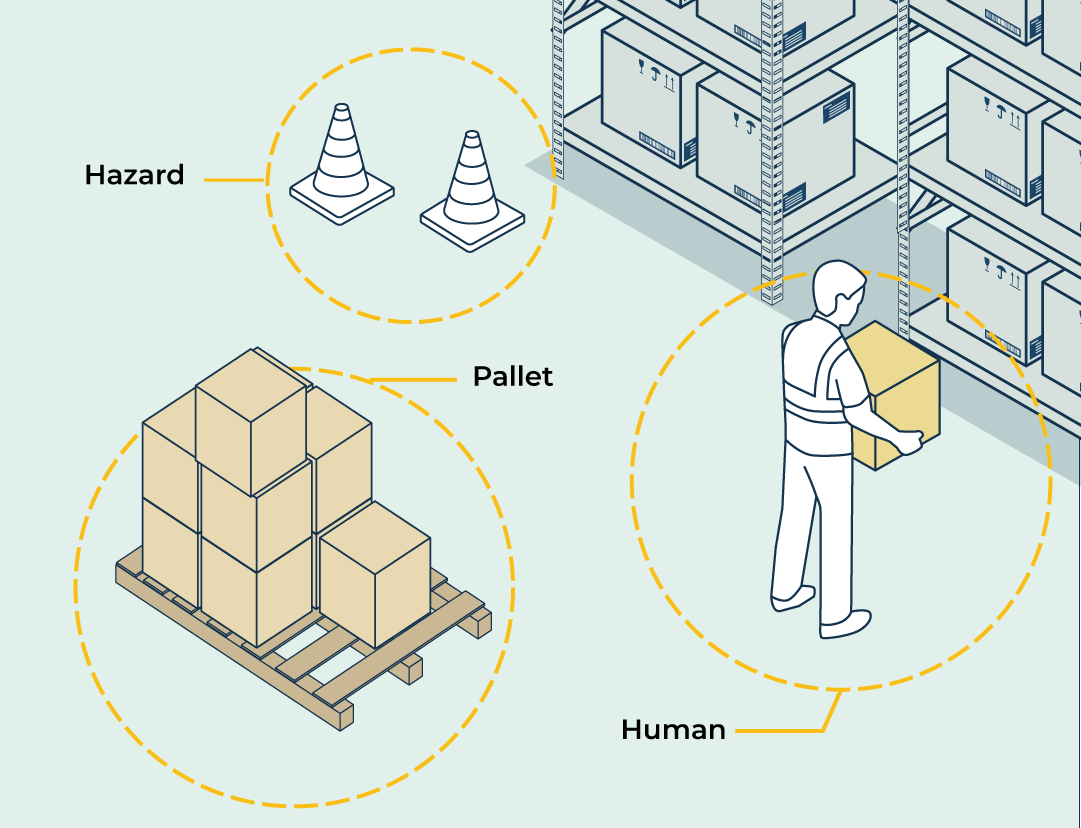

AI Vision

AI-powered computer vision systems are used that replicate human-like decision-making in real time. They don’t just detect objects, they identify pallets, people, and dynamic obstacles, even in low light or crowded spaces. With edge computing at the core, the system processes data locally, reducing dependency on cloud communication and network latency. This smarter perception enables precise object placement, safer navigation, accurate pickups and seamless interaction with complex warehouse environments, without relying on markers, reflectors, or heavy IT integration.

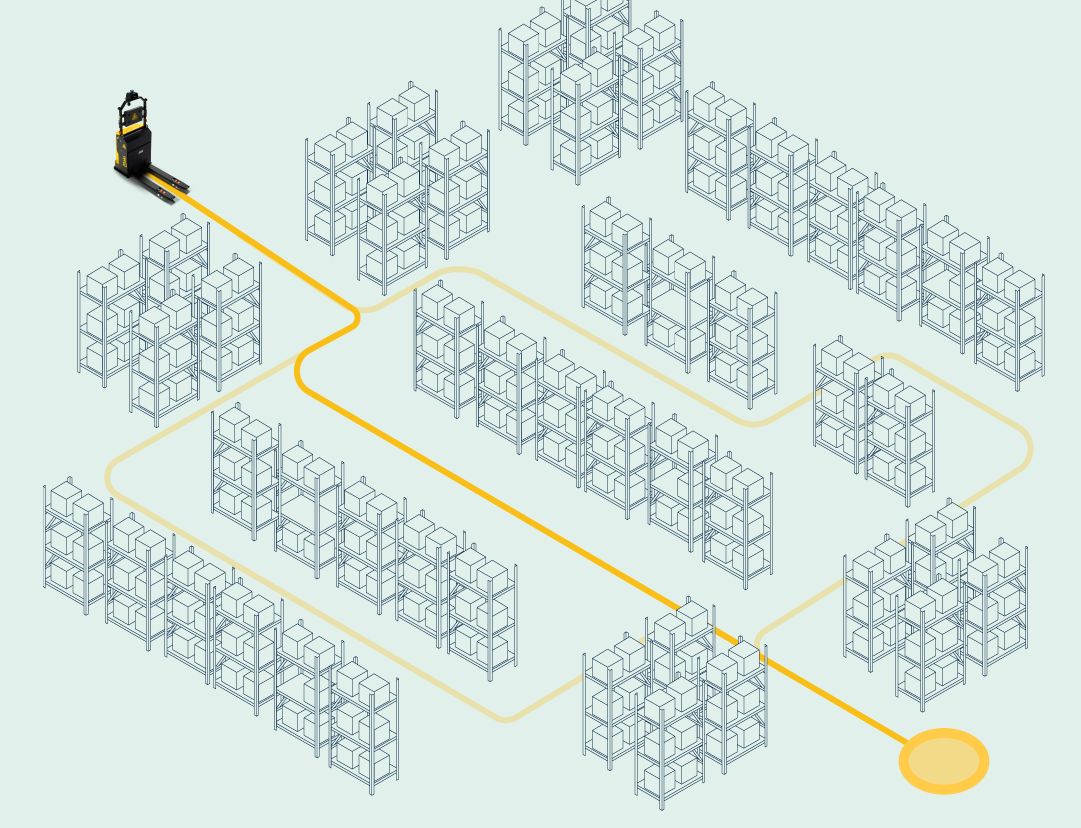

Path Planning

An intelligent path planning engine dynamically calculates the most efficient routes in real time, even in busy or changing environments. Powered by advanced algorithms and live sensor data, our robots avoid congestion, reroute around obstacles, and optimize travel time. The result: lower CAPEX, fewer number of robots, faster task completion, reduced idle time, and smooth autonomous flow across your facility.

Detailed Robot Features

Primary Features of Atlas AC2000

The Atlas AC2000 leverages advanced LiDAR-based navigation, real-time obstacle

detection, and precision control algorithms to autonomously handle truck loading

and unloading tasks, delivering safe, 24/7 material movement with seamless WMS

and ERP integration

LiDAR Sensors – Scanning

Equipped with sensors, cameras and LiDAR systems to detect obstacles and people in their path. They can slow down or stop to prevent collisions

Safety Features

Robot is equipped with collision avoidance technology and emergency stop for operating safety.

Manual Override

Ensures uninterrupted operations by giving you instant control during unexpected stoppages

Powerful Software

Intuitive, real-time control platform for monitoring, managing, and optimizing robot performance. Providing clear insights and seamless integration with warehouse operations.

Specifications

Rated Capacity

4409 lbs (2000kg)

Navigation Method

Laser SLAM navigation

Lifting Height

14.7 ft & 8.2 ft (4500 mm & 2500 mm)

Aisle Width

11.8 ft (3574 mm)

Dimensions (L X W X H)

10 X 4 X 7 ft (3291 X 1250 X 2194 mm)

Fork Dimension (LES)

42.12/3.93/1.77 in (1070/100/45 mm)

Max Traveling Speed

7.4 mph (3.3 m/s)

Body Weight

8686 lbs (3940 kg)

Positional Accuracy

(+/- 0.4”) (+/- 10 mm)

Primary Features of Maia 2000

Engineered with SLAM navigation, real time traffic management, and intelligent pallet

detection, the Maia 2000 ensures efficient and uninterrupted ground-to-ground

transport of closed pallets, perfectly integrating with digital warehouse ecosystems

LiDAR Sensors – Scanning

Equipped with sensors, cameras and LiDAR systems to detect obstacles and people in their path. They can slow down or stop to prevent collisions

Safety Features

Robot is equipped with collision avoidance technology and emergency stop for operating safety.

Manual Override

Ensures uninterrupted operations by giving you instant control during unexpected stoppages

Powerful Software

Intuitive, real-time control platform for monitoring, managing, and optimizing robot performance. Providing clear insights and seamless integration with warehouse operations.

Specifications

Rated Capacity

4409 lbs (2000kg)

Navigation Method

Laser SLAM navigation

Lifting Height

7 inches

Aisle Width (For 40”x48” Pallet)

6.7 ft (2042 mm)

Dimensions (L X W X H)

6 X 3 X 6.67 ft (1837 X 901 X 2025 mm)

Fork Size (LES)

42.12/3.93/1.77 in (1070/100/45 mm)

Max Traveling Speed

5.6 mph (2.5 m/s)

Body Weight

1212 lbs (550 kg)

Positional Accuracy

(+/- 0.4”) (+/- 10 mm)

Factory Automation Solutions

Nortek Automation

Through our partnership with Nortek Automation, we deliver custom automation solutions perfected over 35+ years. Specializing in:

- Print and apply labeling systems

- Packaging automation

- Laser marking systems

- Product handling and sortation

- Custom integration services

Their proven track record in electronics, automotive, and life sciences brings reliable automation expertise to complement our RaaS offerings.